February 2024

Dissolved Oxygen (DO)

INDUSTRIAL STANDARDS

for oxygen content and allowable metal oxide levels in feedwater are required to ensure that system components and surfaces are protected, and the life of those components and surfaces are extended. This is accomplished through mechanical deaeration methods and supplemented by properly applied chemical oxygen scavengers.

It is a well-known fact that corrosive gases such as

Dissolved Oxygen (DO)

are present in feedwater to steam boilers. Because oxygen is a highly active element, if it is allowed to enter the boiler, it will result in the attacking of the boiler internal heat transfer surfaces. It is, therefore, imperative that these gases be removed from the feedwater prior to its introduction into the steam generating equipment.

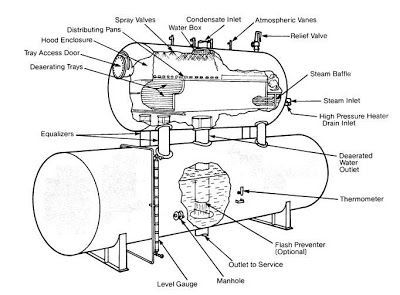

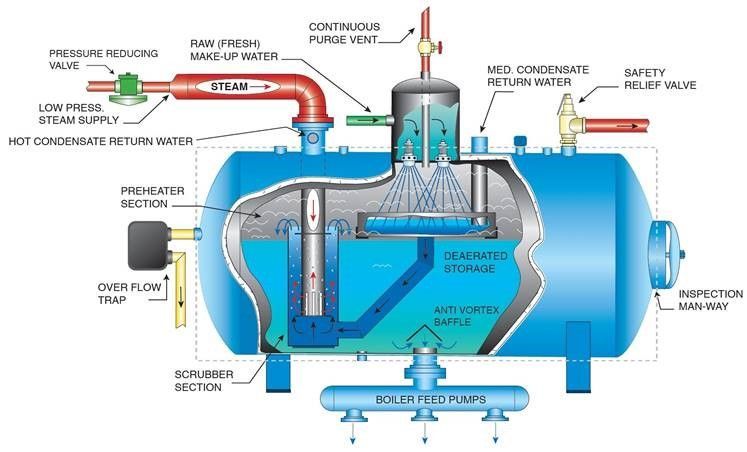

MECHANICAL DEAERATION takes place inside a deaeration (DA) tank that mechanically removes the dissolved oxygen from the feedwater prior to it being directed to the boiler. This requires the use of specialized equipment that raises the temperature of the water while increasing the surface area of the water being treated. This results in the release of the dissolved oxygen from the water where it is vented into the atmosphere. Mechanical deaeration can reduce the dissolved oxygen content to less than 10 parts per billion (ppb) depending on the design and operation of the equipment.

PRINCIPLES THAT APPLY TO THE MECHANICAL DEAERATION OF FEEDWATER

- Solubility of any non-condensable gas in the liquid is directly proportional to the partial pressure of that gas above the liquid surface.

- The solubility of a gas, in a liquid, decreases with an increase in the temperature of that liquid.

- The rate of escape of a non-condensable gas from a given volume of liquid may be increased by increasing the surface area of the liquid.

IMPORTANT CONSIDERATIONS IN THE OPERATION OF A DEAERATING HEATER

- Heat the feedwater to as high a temperature as possible.

- Feedwater surface area must be increased by means of appropriate spray and tray design.

- Vigorously scrub the heater with fresh steam which can carry out to the liquid surface any remaining minute traces of dissolved oxygen.

- The partial pressure of oxygen must be maintained as low as possible in the steam atmosphere in contact with the feedwater.

- Feed and maintain a proper level of chemical oxygen scavenger to ensure that the remaining dissolved oxygen is tied up.

CHEMICAL DEAERATION involves the removal of dissolved oxygen by chemical means. There are many oxygen scavengers available for use in the removal of dissolved oxygen. Some examples are sulfite (SO₃²⁻), hydrazine (N₂H₄), diethylhydroxylamine (DEHA), and many others. These materials create the reaction with dissolved oxygen to tie up the oxygen and prevent it from reacting with the internal heat transfer surfaces in the system thus preventing corrosion in that system.

MECHANICAL OR CHEMICAL DISSOLVED OXYGEN REMOVAL?

So which method is the best for the removal of dissolved oxygen? The answer is both. Mechanical deaeration will not remove 100% of the dissolved oxygen. Good mechanical deaeration followed by chemical oxygen scavenging is the best method to gain complete control of the dissolved oxygen in your system.

Water for Food, Water for Industry, Water for Life

Call and discuss your water and waste water treatment needs with WATERTECH today.

2536 Kimberly Road

Twin Falls, Idaho 83301

(800) 367-3250